MerlinGuard Control Panel

The AGS Controls MerlinGuard is a gas detection & ventilation panel to be used with up to sixteen (16) AGSTFT detectors. It is intended for use in spaces that require either refrigerant, toxic or combustible gas detection and provides a pre-programmed control panel including features such as fan control options, alarm damper control, and connectivity to Building Management Systems (BMS).

The panel has four output options for pre-alarm and high-alarm conditions, and contains a 0-10V output that can be utilized by the BMS or for fan control via VFD.

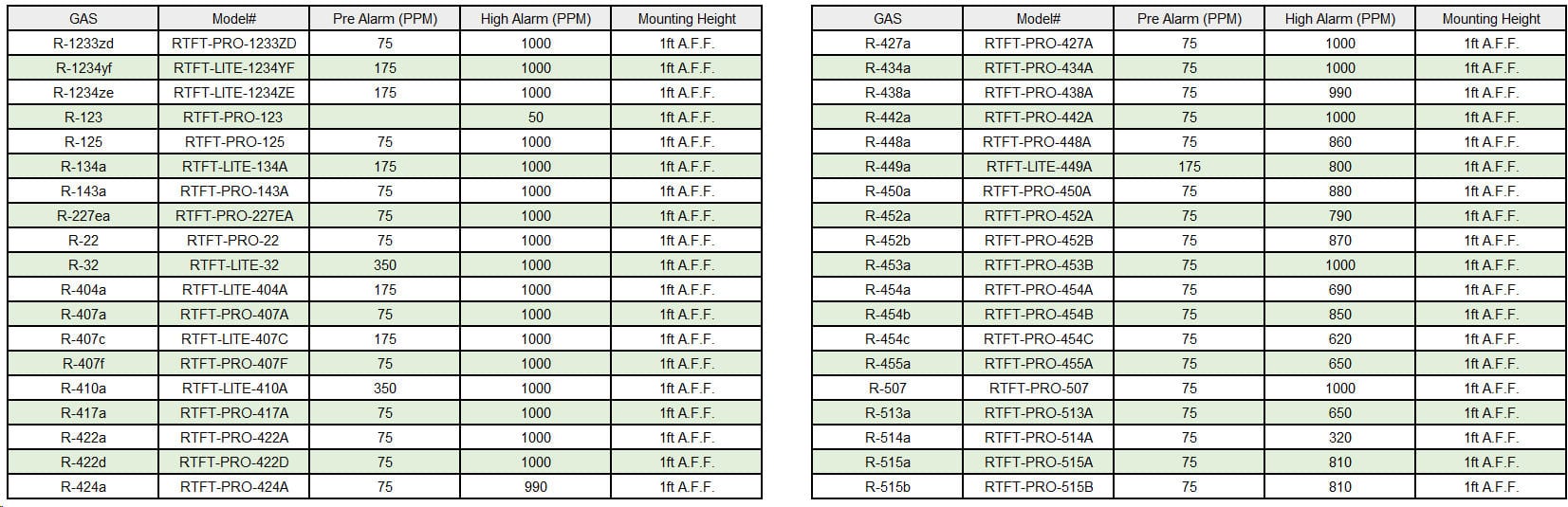

Refrigerant Detectors

Audible Alarm Strobe

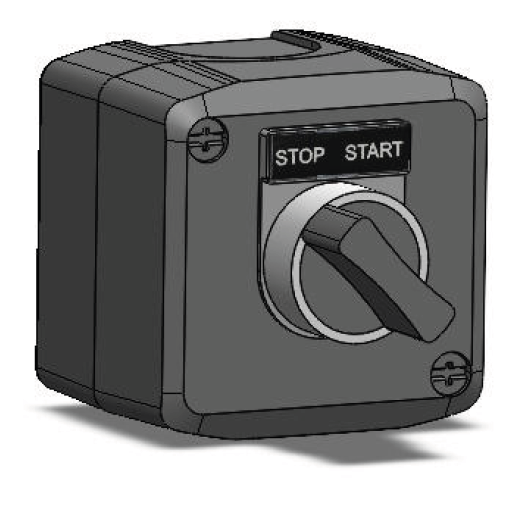

Manual Fan Switch

Product Information

ASHRAE 15 2022:

8.9 Refrigerating Machinery Room, General Requirements.

When a refrigerating system is located indoors and a machinery room is required by section 7.4, the machinery room shall be in accordance with the following provisions.

8.9.5 Each refrigerating machinery room shall contain a detector, located in an area where refrigerant from a leak will concentrate, that actuates an alarm and mechanical ventilation in accordance with Section 8.9.7 at a set point not greater than the occupational exposure limit (OEL) value as published in ASHRAE 34. For refrigerants that do not have a published OEL value in Standard 34, a set point determine in accordance with OEL as designed by Standard 34 shall be approved by the AHJ. The alarm shall annunciate visual and audible alarms inside the refrigerating machineryr room and outside each entrance to the refrigerating machinery room. The alarms required in this section shall be of the manual reset type with the reset located inside hte refrigeranting machinery room. Alarms set at other levels (such as IDLH) and automatic reset alarms are permitted in addition to those required by this section. The meaning of each alarm shall be clearly marked by signage near the annunciators.

IFC 2021:

608.9

Machinery rooms shall be provided with a refrigerant detector with an audible and visual alarm. Where ammonia used as the refrigerant, detection shall comply with IIAR 2. For refrigerants other than ammonia, refrigerant detection shall comply with Section 608.9.1.

608.9.1 Refrigerants other than ammonia.

A detector, or a sampling tube that draws air to a detector, shall be provided at an approved location where refrigerant from a leak is expected to accumulate. The system shall be designed to initiate audible and visible alarms inside of and outside each entrance to the refrigerating machinery room and transmit a signal to an approved location where the concentration of refrigerant detected exceeds the lesser of the following:

1) The corresponding TLV-TWA values shown in the International Mechanical Code for the refrigerant classification.

2) Twenty-give percent of the lower flammable limit (LFL)

Detection of a refrigerant concentration exceeding the upper detection limit or 25 percent of the lower flammable limit (LFL), which is lower, shall stop refrigerant equipment in the machinery room in accordance with Section 608.10.1.

608.9

Machinery rooms shall be provided with a refrigerant detector with an audible and visual alarm. Where ammonia used as the refrigerant, detection shall comply with IIAR 2. For refrigerants other than ammonia, refrigerant detection shall comply with Section 608.9.1.

608.9.1 Refrigerants other than ammonia.

A detector, or a sampling tube that draws air to a detector, shall be provided at an approved location where refrigerant from a leak is expected to accumulate. The system shall be designed to initiate audible and visible alarms inside of and outside each entrance to the refrigerating machinery room and transmit a signal to an approved location where the concentration of refrigerant detected exceeds the lesser of the following:

608.10.1 Refrigeration system emergency shutoff.

A clearly identified switch of the break-glass type or with an approved tamper-resistant cover shall provide off-only control of refrigerant compressors, refrigerant pumps and normally closed automatic refrigerant valves located in the machinery room. Additionally, this equipment shall be automatically shut off when the refrigerant vapor concentration in the machinery room exceeds the vapor detector’s upper detection limit or 25 percent of the LEL, whichever is lower.

608.10.2 Ventilation System

A clearly identified switch of the break-glass type or with an approved tamper-resistant cover shall provide on-only control of the machinery room ventilation fans.

American Gas Safety (AGS) is a manufacturer of gas detection systems and can provide off the shelf systems to comply with the following codes. This document will provide a breakdown of the codes, with specific code language, as well as notes from AGS to comment, clarify things, and note about how our system meets the codes.

Please utilize this document, in addition to other known ASHRAE codes.

ASHRAE 34 RCL LIMIT BREAKDOWN

ASHRAE 34 defines the maximum amount of refrigerant that is allowed to be used within a single volume of space by defining Refrigerant Concentration Limits (RCL) for each type of refrigerant.

The RCL is given in units of LB/1000ft³, and serves as a limit to how much refrigerant is allowed in pounds per volume of the space.

The RCL is the concentration in which each refrigerant becomes immediately hazardous to humans, or explosive if sooner than toxic, and is often significantly higher than the Occupational Exposure Limit (OEL), which is the chronic exposure limit.

The way the code can be conceptualized is if all the refrigerant in your chiller leaks out into the volume in which it sits, and it rises above the RCL limit, then you must follow the machinery room requirements have a detection system.

7.4 Location in a Machinery Room or Outdoors. All components containing refrigerant shall be located either in a machinery room or outdoors, where the quantity of refrigerant needed exceeds the limits defined by Sections 7.2 and 7.3. Refrigeration systems located outdoors shall comply with Section 8.12. (2024 Standard).

Section 7.2 offers details for calculating the volume (effective dispersal volume), and section 7.3 offers details on calculating the maximum amount of charge allowed in the system.

Example:

The “total charge allowed” is referred to in ASHRAE 15 as the effective dispersal volume charge (EDVC).

The correction factor of 1000 is used in the calculations, because ASHRAE 34 gives the RCL limit in LB/1000FT³, rather than LB/FT³.

If your system exceeds these limitations, then you must locate your refrigeration equipment outdoors, or inside of a Machinery Room. It is in the Machinery Room Requirements that the detection system is outlined.

REFRIGERANT TYPES AND WHAT TO FOLLOW

|

REFRIGERANT TYPE |

APPLICABLE CODE SECTION |

|

A1 and B1 |

Section 8.9 |

|

A2, A3, B2, and B3 |

Section 8.9 and 8.10 |

|

A2L or B2L |

8.9.1 – 8.9.4 & 8.11 |

Reference

7.4 Location in a Machinery Room or Outdoors. All components containing refrigerant shall be located either in a machinery room or outdoors, where the quantity of refrigerant needed exceeds the limits defined by Sections 7.2 and 7.3. Refrigeration systems located outdoors shall comply with Section 8.12.

Exceptions to 7.4: … see full code

7.4.1 Direct-fired absorption equipment shall be located in a machinery room or outdoors.

7.4.2 Class 1 Refrigerants. Machinery rooms required by Section 7.4 and containing only Group A1 or B1 refrigerants shall be constructed and maintained in accordance with Section 8.9.

7.4.3* Class 2L, Class 2, and Class 3 Refrigerants. Machinery rooms required by Section 7.4 and containing any Group A2, A3, B2, or B3 flammable refrigerants shall be constructed and maintained in accordance with Sections 8.9 and 8.10. Machinery rooms required by Section 7.4, containing any Group A2L or B2L flammable refrigerants and containing no Group A2, A3, B2, or B3 flammable refrigerants, shall be constructed and maintained in accordance with Sections 8.9.1 through 8.9.4 and Section 8.11.

A1 TYPE REFRIGERANT DETECTION CODE

(2024&2022) 8.9.5 Each machinery room shall contain a refrigerant detector, located in an area where refrigerant from a leak will concentrate, that actuates an alarm and mechanical ventilation in accordance with Section 8.9.6 at a set point not greater than the occupational exposure limit (OEL) value as published in ASHRAE Standard 34.³ For refrigerants that do not have a published OEL value in Standard 34, a set point determined in accordance with the OEL as defined by Standard 34 shall be approved by the AHJ. The alarm shall annunciate visual and audible alarms inside the machinery room and outside each entrance to the machinery room. The alarms required in this section shall be of the manual-reset type with the reset located inside the machinery room. Alarms set at other levels (such as IDLH) and automatic reset alarms are permitted in addition to those required by this section. The meaning of each alarm shall be clearly marked by signage near the annunciators.

Located in an area where refrigerant from a leak will concentrate: Check refrigerant weight to determine if it will rise or fall, and install detectors at appropriate heights based on the AGS manual. Detectors can be wall-mounted near chillers or ceiling-hung at high-risk points.

Actuates an alarm and mechanical ventilation: The system must trigger ventilation at 100 times the square root of the refrigerant charge during a leak (8.9.8.1).

Set Point (Alarm Levels), Occupational Exposure Limit (OEL): The OEL is the TWA concentration for an eight-hour workday, based on OSHA PEL, ACGIH TLV, or equivalent, as outlined in ASHRAE 34.

Annunciate Visual and Audible Alarms: Visual and audible alarms can be installed outside entrances and inside the room, connected to the control panel or using built-in strobe units.

Shall be of the manual reset type: The AGS MerlinGuard requires a manual reset after a high alarm, with the reset located inside the chiller room.

A2L TYPE REFRIGERANT DETECTION CODE

Chapter 8 Section 11 (2024) lays out the requirements for machinery room designs that include A2L type refrigerants.

A basic rundown of these requirements is as follows:

(2024&2022) 8.11.6 Where any refrigerant of Groups A2, A3, B2, or B3 are used, the machinery room shall be designated as Class I, Division 2 hazardous (classified) electrical location in accordance with the National Electric Code® (NFPA 70).⁴

Where flammable refrigerants only from Groups A2L or B2L are used, the machinery room shall meet one of the following requirements:

a. Be provided with ventilation per Section 8.11.6.1 and refrigerant detection per Section 8.11.6.2.

b. Be designated as Class I, Division 2 hazardous (classified) electrical location in accordance with NFPA 70, and be provided with ventilation per Section 8.9.6 and refrigerant detection per Section 8.11.6.2. Compliance with Section 8.11.11 shall not be required.

(2024&2022) 8.11.6.1 The machinery room shall have a mechanical ventilation system in accordance with Section 8.11.11. The mechanical ventilation system shall

a. Run continuously, and failure of the mechanical ventilation system actuates an alarm or

b. Be activated by one or more refrigerant detectors, conforming to requirements of Section 8.11.8

AGS Note: The mechanical ventilation system should be activated at no more than the OEL limit of the refrigerant.

(2024&2022) 8.11.6.2 Detection of refrigerant concentration that exceeds 25% of the lower flammability limit (LFL) or the upper detection limit of the refrigerant detector, whichever is lower, shall automatically de-energize the following equipment in the machinery room:

a. Refrigerant compressors

b. Refrigerant pumps

c. Normally closed automatic refrigerant valves

d. Other unclassified electrical sources of ignition with apparent power rating greater than 1 kVA, where the apparent power is the product of the circuit voltage and current rating

(2024&2022) 8.11.7 Remote control of the mechanical equipment in the machinery room shall be provided immediately outside the machinery room door solely for the purpose of shutting down the equipment in an emergency. Ventilation fans shall be on a separate electrical circuit and have a control switch located immediately outside the machinery room door.

AGS Note: AGSESOTW is provided outside of each exit. The AGSMGFS manual fan switch is placed outside of the door with the AGSESOTW to satisfy the manual fan switch section of this code. The AGSMGFS shall provide the minimum Level 1 airflow rate that is required for when personnel enter the room (8.11.11.2).

(2024&2022) 8.11.8 Each machinery room in accordance with Section 8.11 shall contain one or more refrigerant detectors in accordance with Section 8.11.9, with sensing element located in areas where refrigerant from a leak will concentrate, with one or more set points that activate responses in accordance with Section 8.11.10 for alarms and Section 8.11.11 for mechanical ventilation. Multiport-type devices shall be prohibited.

(2024&2022) 8.11.8 Each machinery room in accordance with Section 8.11 shall contain one or more refrigerant detectors in accordance with Section 8.11.9, with sensing element located in areas where refrigerant from a leak will concentrate, with one or more set points that activate responses in accordance with Section 8.11.10 for alarms and Section 8.11.11 for mechanical ventilation. Multiport-type devices shall be prohibited.

(2024&2022) 8.11.9 Refrigerant detectors required by Section 8.11.8 shall meet all of the following conditions:

a. A refrigerant detector shall be capable of detecting each of the specific refrigerant designations in the machinery room.

b. The refrigerant detector shall activate responses within a time not to exceed a limit specified in Sections 8.11.10 and 8.11.11 after exposure to refrigerant concentration exceeding a limit value specified in Sections 8.11.10 and 8.11.11.

c. The refrigerant detector shall have a set point not greater than the applicable OEL value as published in ASHRAE Standard 34.³ The applicable OEL value shall be the lowest OEL value for any refrigerant designation in the machinery room. For refrigerants that do not have a published OEL value in Standard 34, use a value determined in accordance with the OEL as defined by Standard 34 where approved by the AHJ.

d. The refrigerant detector shall have a set point not greater than the applicable refrigerant concentration limit (RCL) value as published in ASHRAE Standard 34.³ The applicable RCL value shall be the lowest RCL value for any refrigerant designation in the machinery room. For refrigerants that do not have a published RCL value in Standard 34, use a value determined in accordance with the RCL as defined by Standard 34 where approved by the AHJ.

e. The refrigerant detector shall provide a means for automatic self-testing and shall be in accordance with Section 8.11.10.4. The refrigerant detector shall be tested during installation and annually thereafter, or at an interval not exceeding the manufacturer’s installation instructions, whichever is less. Testing shall verify compliance with the alarm set points and response times per Sections 8.11.10 and 8.11.11.

8.11.10 Alarms required by Section 8.11.8 shall comply with the following.

8.11.10.1 The alarm shall have visual and audible annunciation inside the machinery room and outside each entrance to the machinery room.

8.11.10.2 The refrigerant detector set points shall activate an alarm in accordance with the type of reset in Table 8-1. Manual-reset type alarms shall have the reset located inside the machinery room.

Product Applications

Get in touch

Have a question? Our team can help.